I contacted Clayton Boyer ,regarding weights and running times of his clocks, most run for 25-30 hours with up to 7lb weight. All arbors and bushes was machined from lignum vitae, turned on a metal turning lathe. The wheels were cut from satin box I laminated ,starting at 12mm for winding wheels down to 6mm teeth for the 2nd wheel. the rest of the working are normal wheels and pinions. The 60t drives a 20t fixed to the minute arbor that revolves inside the hour bush.

#Wooden work clock movement free

The 16t drives a 64t fixed to a bush which takes the hour hand ,this is free running over the minute arbor. Working from the winding arbor,I have a 16t and a 60t fixed together but free running with the ratchet fitted to the 60t.

I'll try and explain what I done to over come this. Just about all wooden clocks have the hour and minute wheels in front of the clock workings,I think they detract from the clocks general appearance. Rhys, Sorry about the delay answering your queries about my wooden clock. The experts also recommend that the teeth are left with absolutely no finish on them and are left as bare wood which the graphite sticks to and wears in.

As time goes by the clock is becoming less affected by the humidity as the high spots on the bearings and teeth are wearing in. I would think that with Oak there would be very little penetration at all. I have seen your clocks on the forum and greatly admired them.Įchinada, I did try to soak some swamp kauri with a thinned epoxy and was really disappointed to see how little penetration it had. Wood clock movement (841 Results) High Torque Quartz Clock Movement Quiet Sweep Motion clockparts (833) 14.95 FREE shipping METIE wood handmade clock hands movement 6168 supplies, DIY clock Metieart (7) 10. The clock needs 5lbs to run but with a 4:1 set of pulleys it obviously has 20 lbs on it but still only 5 lbs on the weight arbor. The next one will have brass bushings on the dowel arbors or perhaps brass rods. Enormous quantities were produced for affordably priced shelf clocks. I had wanted my first clock to be on traditional lines in much the same way that they were built originally thus it is all wood. Production of the 30-hour wooden shelf clock move - ment began about 1816 and continued to about 1845. The clock is designed by Better Homes & Gardens WOOD Magazine (Nov. The timber used throughout is oak and the arbors run in holes that have been burnished out to be slightly oversize to give clearance and are then lubricated with graphite powder. Hi-torque clock movements that work great for building a very large clock. There are paper patterns but I was reluctant to cut them up as one then has no reference point and I discovered that zerox prints are not accurate thus I made up a jig mounted on an index plate and marked the teeth out before cutting them. I cut them all out on my Hegner scroll saw and finished the teeth on a 1"x 42" vertical belt sander on which I run a 240 grit belt which I have slowed down from its original speed by changing the drive pulley.

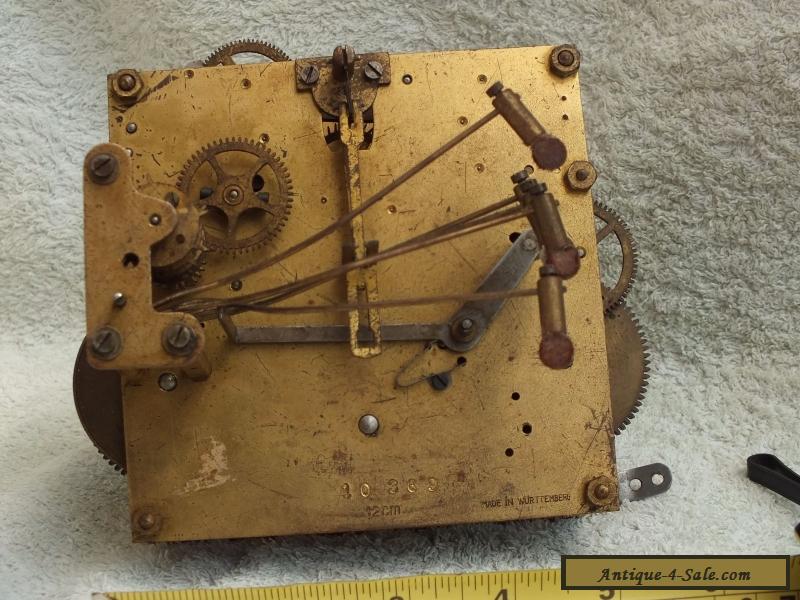

The wheels, pinions etc were made from self made 5 ply oak and finished at 12mm. I made up the front and rear panels from 3ply which I made from the oak and glued with epoxy glue. ThanksIf you have any additional questions or concerns, please don't nd an email and we will respond as quickly as we can.John, I built the clock from European oak which I bought in 200 x 25 rough sawn. World Wide customers, please ask about shipping cost and insurance cost. Insurance is included in shipping and handling calculation for all items greater than $50 in final selling price. We will ship USPS Parcel Select or Fed Ex(Heavier & greater distances) unless you have a strong desire for another delivery service. Antique 1830’s Wood Works clock movement with brass escapement gear, excellent shape Weight driven, original cord missing on one main wheel Plates measure 6 ½” x 8” 3 ½” from center to center of winding arbors 2 ¾” from hand arbor to winding arbor Appears to be complete with a little dust I noticed one great looking repair to main drive gear(picture) Great estate find in CT, Sold “as is” We accept PAY PAL or personal checks.

0 kommentar(er)

0 kommentar(er)